H-Forms Helix MircoRebar

No Labor Required to Install

Superior to Standard Rebar

Makes concrete more durable

Produces concrete that’s 4x stronger with less than half the tonnage of steel

Improves shear strength and absorbs 200% more energy

Prevents spalling due to steel corrosion / expansion

Reduces rebar congestion in multiple mat slabs - replaces rebar or increases spacing of rebar

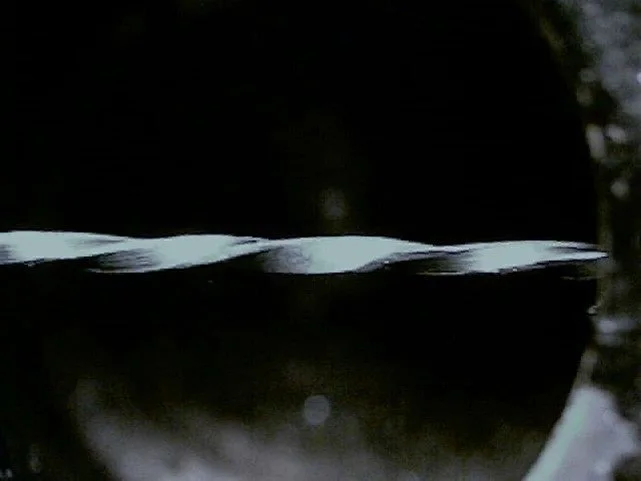

Provides a multi-directional matrix of reinforcement 1-inch long twisted high carbon steel rods

Minimizes concrete cracking - meeting guidelines of the American Concrete Institute (ACI)

Meets or exceeds Uniform Evaluation Service (UES) Report EC 105 requirements

Reduced carbon footprint through reduced total steel quantity and potential reduced concrete thickness

Rust-resistant (Zinc Electroplated)

Zinc coating resists rust 3x longer than uncoated rebar

Structural Foundations

Footings

Slabs

Post-Stresses and Pre-Stressed Floors and Slabs

Structural Floors

Landscaping Flatwork, Driveways, Airport Runways and Roads

Structural Walls (especially ICF Walls)

Beams, Columns and Piers

Bridges and Highways

Precast Products

Sanitary, Storm and Culvert Products

Tilt-up Construction

Shotcrete and Gunite (pumps easily, even through a 2-inch hose)

Winery Caves, Freeway Tunnels and Reservoirs

Swimming Pools

Uses for H-Forms Helix MicroRebar

Made with recycled American steel

Reduces your carbon footprint by 33% compared to standard rebar, and helps you achieve your LEED goal

Reduces the emissions or transport because it requires one-quarter the weight of standard rebar rods

For Future Generations

Pours and finishes like any concrete

Compatible with common curing compounds, dry shake or spray-on toppings

Can be mixed at the batch plant or on the job site (takes minutes per truck)

Eliminates estimating, storing, cutting, bending, placing and tying most rebar steel. In most Seismic areas, designs need a hybrid of standard rebar in high shear places but most can be replaced.

Eliminates fabricating cages for deep piers

H-Forms Helix MicroRebar will provide engineering comparison calculations with your conventional steel design at no charge to show you how few conventional steel rods you will need along with the Helix doses.

Far Easier than Standard Rebar

Save Time, Labor and Money

Saves 10% - 30% the cost of concrete work on your next project

Eliminates all estimating and the only labor needed is to sift the Helix into the ready-mix drum on site or in the batch plant, plus a 5-minute full-speed final mixing

Reduces or eliminates the time and expense of skilled labor to estimate, cut, bend and tie steel

Weighs only one-quarter of the weight of standard rebar rods for the same job

Shipped in 7” x 10” x 14”, 47 lbs. boxes (Helix is 45 lbs.)

No need for the expense of semi trucks, forklifts or cranes

Even UPS can deliver!

Makes for a safer job site - reduces or eliminates:

The danger of vertical bars (eye injury)

The tripping hazard of standard rebar mats